PET Blowing-Filling-Capping units

The BFC-unit incorporates a stretch blow molding machine to produce plastic bottles from PET preforms, followed by a filling and capping machine. All operations are automated.

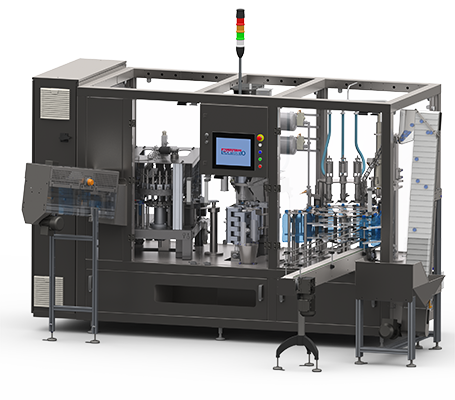

The entire bottling system, model OPTIMA, is built according to clean design requirements on a single frame and foreseen with a central control panel.

The blowing clamp and the stretch rod are electronically driven by a servo motor for optimal adjustments.

The filling principle depend on the type of liquid. Depending the type of cap, we foresee pick-and-place or sweep-off capping applicators.

- very flexible with neck-handling throughout the entire bottling process

- bottle format change-over takes only 20 minutes (identical preform neck diameter)

- compact with easy access to all important parts, facilitating maintenance

- the visibility for the operator on all parts of the machine is outstanding

- can be equipped with a remote data control and monitoring system

OPTIMA 1:

Output

1600 bottles per hour

Bottle volume

from 0.2 to 2.5 liters

Bottle type

cylindrical

Molds

1 unit

Stretch rod unit

servo driven

Heating ovens

up to 2

Filling nozzles

up to 4

Capper

1 capping head

Machine dimensions (LxWxH)

3500 x 1500 x 2000 mm

Weight

1800 kg

OPTIMA 2 (Coming soon)

Output

3200 bottles per hour

Bottle volume

from 0.2 to 2.5 liters

Bottle type

cylindrical

Molds

2 units

Stretch rod unit

servo driven

Heating ovens

up to 4

Filling nozzles

up to 5

Capper

1 capping head ‘sweep off’ or 3 heads, rotary

OPTIMA 3 (Coming soon)

Output

4800 bottles per hour

Bottle volume

from 0.2 to 2.5 liters

Bottle type

cylindrical

Molds

3 units

Stretch rod unit

servo driven

Heating ovens

up to 4

Filling nozzles

up to 5

Capper

4 heads, rotary

Main data may change depending on options or technical aspects

- Low pressure mold

- UV treatment on air, preforms, caps (and water)

- Labeler on bottle outfeed conveyor

- Laser on bottle outfeed conveyor

- Electrical cabinet in stainless steel

- Bottle design development

- HEPA: air filtering system

- Utilities: compressor, chiller, dryer

Containerized PET

blowing plant:

An OPTIMA 1 (PET blower-filler-capper) unit can be built inside a 20ft sea-container, equipped with utilities, such as compressor, dryer and chiller.